|

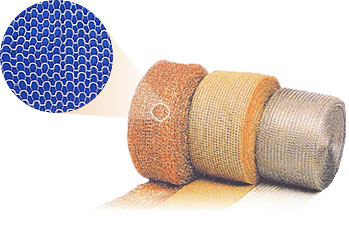

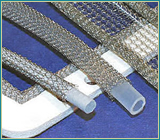

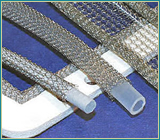

Knitted wire mesh gaskets provide a cost effective solution to high shielding performance applications in the magnetic and electrical fields including EMP. Gaskets can be either all metal knitted mesh (100 series) or knitted metal mesh over an elastomer core (200 series) to allow for recovery after compression. The choice of wire mesh material allows for a good galvanic match with mating flanges, thereby limiting the possibility of corrosion between gasket and flange.

|

| |

|

|

Knitted wire mesh gaskets are made from stainless steel wire materials which offer good corrosion resistance against acid and alkali.

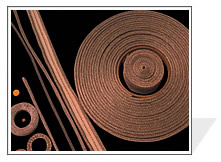

It can be supplied in rolls, tube or cut forms.

Material available: Stainless steel wire, galvanized iron wire, red copper wire, phosphor bronze wire, nickel wire, polyamide fiber, polyester fiber, F46 fiber, metal wire and mixed fiber, etc.

Application: In distillation, absorption, evaporation, filtration in the process of petroleum, oil refining, chemical industry, light industry, pharmacy, metallurgy, machinery, ship-making, automobiles and tractors, to delete the mist drop or liquid foam in air, also used as air filter in cars and tractors.

Properties of Knitted Mesh

Knitted metal has distinct advantages over most competitive materials. Because each loop acts as a small spring when subjected to tensile or compressive stress, knitted metal has an inherent resiliency. If it’s not distorted beyond its yield point, the material will resume its original shape when the stress is removed. Even when it’s compressed into a special shape, a high degree of resiliency is retained. Varying the knitted structure, wire diameter, wire material and forming pressure used to create the part can control this characteristic.

Knitted metal also provides high mechanical damping characteristics and non-linear spring rates. Vibration and mechanical shock can be effectively controlled to eliminate the violent resonant conditions and provide ample protection from dynamic overloads.

In compressed form, knitted metal can handle shock loadings up to the yield strength of the material itself. The load may be applied from any direction—up, down or in from all sides.

Our application engineers have the experience to determine the optimum density of compressed units within the range of 10% to 70%. This is important in applications such as liquid filtration and noise attenuation where flow resistance is critical.

When compressed, layered, calendared or wound knitted metal presents a “tortuous” path to liquids or gasses flowing through it. This increases filtration capability and particle retention capacity."Inconel", "Monel", "Nylon", "Hastelloy", and "Teflon" are registered product names of their respective trademark holders

Mesh Diameters

Mesh is normally knit from wires ranging in diameter from .0035” to .0200”. In special applications, Metex has knit wires ranging in diameter from .0005” to .0350”. These wires can be round or flat such as those used in Metex copper gauze for cleaning and in air-filtration applications where large surface areas of wire are needed. A round wire when flattened has approximately twice as much surface area.

In filtration applications, wire diameter is perhaps the most important design variable. It directly affects flow, dirt holding capacity, pressure drop and cost. In general, larger diameter wire allows for higher flow but provides lower dirt holding capacity. Also, larger diameter wire is less expensive. Therefore, a balance must be struck between using a higher density filter of higher cost fine wire or a lesser density filter using lower cost heavy wire.

Density

Density refers to the mass of material per unit volume. It is related to the density of the original mesh and the amount of forming pressure used to compress the mesh into its final form. Determining the required mesh density to produce the specified final product density is a critical step in the design process. Proper density ensures optimal performance of the sealing, gasketing, filtration, heat transfer and separation applications.

|

|